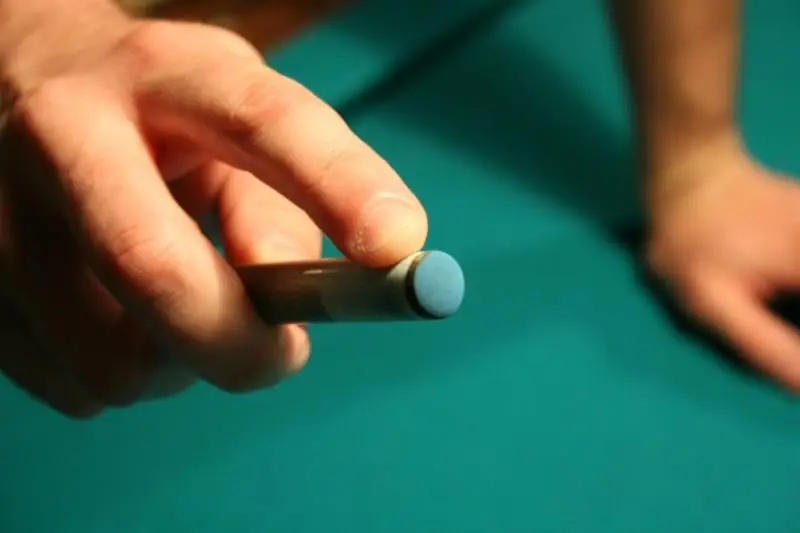

Visually, it is a simple cube with a powdered surface. In practice, it is an indispensable element that determines the control over the impact, grip and stability of the cue. Every professional knows that without a high-quality coating, the cue slips and the direction of the ball becomes unpredictable. The answer to the question of what chalk is used for in billiards goes beyond ritual and becomes a technical justification.

Mechanics of adhesion: what is chalk used for in billiards?

In billiards, a solid object (the tip of the cue) must come into contact with a sphere at a variable angle. At a standard collision speed of approximately 1 m/s, the surface of the ball offers resistance, especially in the case of lateral contact. Without preparing the tip, the cue slips and instead of a precise shot, a parasitic pulling force is created. To eliminate this slipping, a coating is used that provides microfriction. The answer to the question of what chalk is used for in billiards lies precisely in this area: in stabilising the contact angle and fixing the moment of impact.

With a shot at an angle of 15°, the slipping without coating reaches 60% of the total force of the impulse. This causes uncontrolled rotation of the ball and a deviation from the trajectory. The chalk reduces this percentage to 10-12%, maintaining the direction, especially when a sideways spin is applied.

History of billiard chalk: from alabaster to standard

The first references to billiard cues date back to the mid-19th century. Initially, alabaster powder and ground limestone were used, which were applied by hand to leather stickers. The breakthrough came with the invention of a compact block in the shape of a cue.

The first references to billiard cues date back to the mid-19th century. Initially, alabaster powder and ground limestone were used, which were applied by hand to leather stickers. The breakthrough came with the invention of a compact block in the shape of a cue.

The Brunswick company was the first to start mass production. After several experiments with the composition and shape, a universal structure was found. Later, engineer Anthony Pell proposed a formula that increased adhesion by 30%. And inventor William Hoskins obtained a patent for a composition with volcanic rock, which increased the abrasive power and stability of the coating.

Composition of billiard chalk: powder technology

Billiard chalk has nothing to do with its counterpart in office supplies. The basis is a mixture of hard abrasive and softening binder. The standard composition consists of 60 to 80% finely ground limestone, 15 to 20% silicates and 5 to 10% wax or paraffin mixtures. This ratio provides the necessary balance between softness and adhesive strength.

When applied, the chalk particles fill the micro-pores of the sticker, creating an adhesive layer. When struck, this layer partially embeds itself in the surface of the ball, locking in the trajectory. Without this layer, the cue loses control at high speeds, especially with angled or sharp shots.

Practical application: why is chalk necessary in billiards?

Applying chalk requires precision. Circular movements without pressure ensure even coverage. Too much chalk creates unnecessary dust that impairs contact. One layer is effective for up to 2-3 shots. Professionals renew the layer before each critical shot, especially when performing a spin or a precise action with a sideways cut. With a sticker diameter of 12 mm, approximately 0.1-0.2 g of chalk is required for a series of five shots. The thickness of the layer should not exceed 0.2 mm; if it is thicker, the particles begin to come off, fall on the cloth and disrupt the movement of the ball.

How to choose chalk for billiards: criteria and nuances

What type of chalk is needed for billiards: when choosing, you need to take into account the conditions in which you will be playing. There is no universal option: different situations require different properties. The basis for the choice is determined by the structure of the particles, i.e. their size, shape and adhesive properties. For training, a coarse grain composition is most suitable, as it provides reliable contact even with imperfect technique. This chalk forgives mistakes and stays on the cue ball longer, especially during sessions lasting many hours. It helps to stabilise hand movement and is suitable for beginners who are learning the basic shots.

The situation is different in competitions. Here, it is not durability that is important, but the precision of microcontrol. Microdispersion chalk is applied in a thin layer, rubbed in quickly and ensures perfect adhesion with minimal coverage thickness. This is especially important for shots with a fine cut, where fractions of a millimetre determine whether you hit or miss. Classic tournament games require frequent renewal of the layer, but guarantee maximum controllability.

An additional parameter is the behaviour of the chalk in the glue. If applied evenly, the layer should remain in place for at least 2-3 strokes without drying out, crumbling or coming off. At the same time, the glue should not change its structure and the cue should not lose its balance.

Signs of high-quality chalk

Why chalk is necessary for billiards becomes clear during the game. But when choosing chalk on the shop shelf, a clear set of characteristics is required, including:

- Homogeneous texture. Quality chalk has a smooth and finely distributed surface, without impurities, lumps or solid inclusions. Lumps indicate incorrect pressing technology or uneven drying. When applied, this structure causes ‘spots’ that cause the chalk to slip when struck.

- Minimal detachment. Poor-quality chalk detaches from the sticker with a light touch, especially when the cue is at an angle. This loss of adhesion renders the coating ineffective. Good-quality chalk remains on the surface even with a slight vibration.

- Dry but adhesive structure. The surface of the chalk should not be greasy or chalky in the classic sense of the word. When touched, it should not feel like powder or talc. Instead, it should give a slight feeling of ‘adhesion’, which ensures the transfer of microparticles to the cue.

- Permanent marking on the surface of the ball. After impact, a barely noticeable streak or imprint remains on the ball, indicating correct contact and good adhesion. The markings indicate firm contact and high sensitivity of the coating.

- Compatibility with the sticker. When using chalk, the sticker should not crack, soften or lose its shape. Some compositions contain chemical additives that reduce the sticker’s service life by 20-30%. Checking compatibility is a mandatory part of the selection process.

- Absence of oily components. Some cheap samples contain oils or additives that make the chalk visually shinier. These components form a film on the surface of the ball, disrupt the trajectory and increase the coefficient of friction.

- Shape and density of the block. The cube should have well-defined edges, should not crumble when pressed, and should not break when twisted. Low-density chalk crumbles during active play, loses its shape, and quickly becomes unusable. The optimal density is a compromise between ease of application and stability during storage.

Conclusion

Billiards is a game of precision, not power. The entire logic is based on the predictability of contact. This raises the question of what chalk is used for in billiards, not as a decorative element, but as a technical aid to control grip. Professional players never miss an opportunity to renew the layer, because they know that it is not muscle strength that matters, but the coating. And precision in billiards is the result of thousands of correctly prepared shots.

Billiards is a game of precision, not power. The entire logic is based on the predictability of contact. This raises the question of what chalk is used for in billiards, not as a decorative element, but as a technical aid to control grip. Professional players never miss an opportunity to renew the layer, because they know that it is not muscle strength that matters, but the coating. And precision in billiards is the result of thousands of correctly prepared shots.

Success is the result of a combination of many factors, from keube mastery to psychological stability and the ability to maintain concentration during the tournament.

Success is the result of a combination of many factors, from keube mastery to psychological stability and the ability to maintain concentration during the tournament. It is difficult to determine who the best billiard player is because everyone has their own characteristics and merits. Ronnie O’Sullivan impresses with his speed and intuitive understanding of the game; Stephen Hendry, with his perseverance and aggressiveness; Efren Reyes, with the magic of his atypical shots; and Mark Selby, with his stamina and strategic thinking. They are all great in their own way and choosing a leader will always be subjective. The secret of their success is the constant work on themselves, the pursuit of perfection and the ability to overcome difficulties.

It is difficult to determine who the best billiard player is because everyone has their own characteristics and merits. Ronnie O’Sullivan impresses with his speed and intuitive understanding of the game; Stephen Hendry, with his perseverance and aggressiveness; Efren Reyes, with the magic of his atypical shots; and Mark Selby, with his stamina and strategic thinking. They are all great in their own way and choosing a leader will always be subjective. The secret of their success is the constant work on themselves, the pursuit of perfection and the ability to overcome difficulties.

To play, you need the right equipment. The basics are a billiard table, balls, cue and various accessories. A billiard table is usually 9 feet in size, although you can also find 7- and 8-foot tables, which are used for amateur games and confined spaces.

To play, you need the right equipment. The basics are a billiard table, balls, cue and various accessories. A billiard table is usually 9 feet in size, although you can also find 7- and 8-foot tables, which are used for amateur games and confined spaces. More than a pastime, snooker is a real intellectual challenge that requires concentration, precision and planning skills. With its combination of accessible rules and in-depth tactics, snooker has become popular with beginners and professionals alike. It is a game that has something for everyone, whether it is the satisfaction of catching your first ball or the joy of beating a serious opponent. If you haven’t tried snooker yet, it’s time to start!

More than a pastime, snooker is a real intellectual challenge that requires concentration, precision and planning skills. With its combination of accessible rules and in-depth tactics, snooker has become popular with beginners and professionals alike. It is a game that has something for everyone, whether it is the satisfaction of catching your first ball or the joy of beating a serious opponent. If you haven’t tried snooker yet, it’s time to start!